Introduction

In the ever-evolving mining industry, a vital sector of the world economy, we are witnessing a profound technological revolution. From high-capacity, highly automated operations to cutting-edge advancements in automation and robotics, safety and efficiency in mining are being elevated to new heights. Innovative technologies such as 3D scanning and reverse engineering are now pivotal, reshaping the industry and setting new standards for success.

The Role of 3D Scanning in Mining

3D scanning technology has emerged as a pivotal tool in the mining industry. Laser scanning systems, renowned for their speed, accuracy, and safety, can capture the spatial coordinates of objects, creating detailed point clouds that represent scanned objects. These point clouds are then processed into 3D models using CAD software, offering numerous applications in mining operations.

Aerial Inspection and Surveying

Drones equipped with 3D scanners are revolutionizing mining surveys. They provide a quick and cost-effective way to collect precise airborne data, which is essential for improving production planning, safety, and inventory management. By capturing images from various angles and processing them through photogrammetry software, drones can create 3D maps and digital terrain models. This capability is invaluable for tasks such as surveying, mapping, stockpile management, and mining exploration.

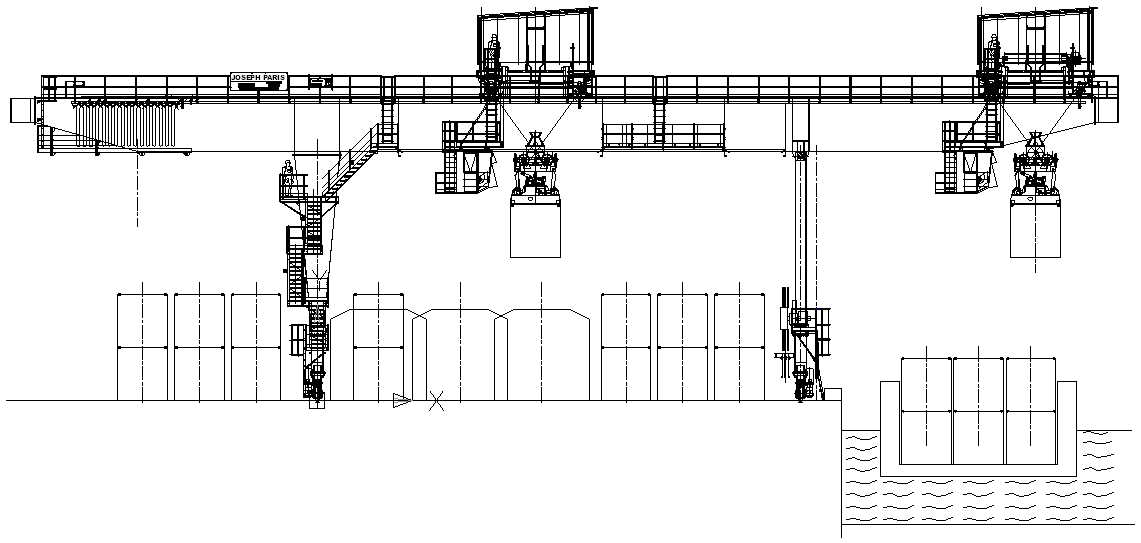

Longwall Systems and Mechanical Engineering

Longwall mining systems, used for efficient underground coal extraction, involve complex mechanical systems like gearboxes, conveyors, and shearers. Maintaining these systems is crucial for continuous operation. Mechanical engineers utilize 3D scanning to inspect and model components, facilitating the repair and optimization of mining equipment. This not only ensures operational efficiency but also enhances safety and reduces downtime.

CAD Design and Digital Twins

In the realm of the mining sector, CAD design emerges as a vital player, providing essential support for the development and upkeep of intricate machinery functioning in challenging conditions. Utilizing digital tools, engineers craft new equipment and revamp current machinery. The concept of digital twins, mirroring physical systems virtually, empowers engineers to conduct FEM analysis, scrutinizing components digitally prior to real-world implementation. Through this virtual prototyping process, early detection of possible challenges enhances the refinement and performance of mining equipment designs.

Reverse Engineering: Enhancing Maintenance and Innovation

Reverse engineering involves deconstructing existing products to understand their design and functionality. In the mining industry, this technique is crucial for maintenance and repair. Often, mining equipment operates under extreme conditions, leading to wear and tear. When original design documents are unavailable, reverse engineering allows engineers to recreate parts or improve existing systems. 3D scanning facilitates this process by providing accurate digital models of the components, which can then be analyzed and reproduced.

Underground Mining Surveys

3D scanning is extensively used in underground mining to survey tunnels and infrastructure. It helps in assessing the contour of tunnel linings and other underground structures, ensuring stability and safety. The technology is also gaining traction in quarries for topographic mapping and monitoring, enabling precise planning and resource management.

Equipment Maintenance

Maintaining heavy-duty mining equipment is challenging due to the complexity and harsh operational environments. Portable 3D scanners allow engineers to quickly and accurately measure and inspect parts, especially those with intricate geometries. This accelerates maintenance processes, reduces downtime, and enhances overall equipment reliability.

Conclusion

The incorporation of 3D scanning and reverse engineering within the mining sector presents significant advantages, spanning enhanced safety, efficiency, and decreased operational expenses. These cutting-edge technologies facilitate thorough inspections, precise data gathering, and the development of digital models that support maintenance and innovation.

As the mining field progresses, the adoption of these advanced tools becomes pivotal for advancing future achievements and sustainability. Harnessing the capabilities of 3D scanning and reverse engineering empowers mining operations to attain elevated levels of accuracy and effectiveness, fostering a more resilient and forward-looking industry.

Nessun commento:

Posta un commento