The steel industry is an important part of the global economy, providing essential materials for construction, transportation, and manufacturing. However, steel production also has a significant environmental impact, contributing to greenhouse gas emissions and other environmental issues. In recent years, there has been growing interest in promoting a circular economy and reducing the environmental footprint of the steel industry.

A circular economy is an economic model that aims to keep resources in use for as long as possible, minimizing waste and reducing the consumption of new resources. In the steel industry, a circular economy can be achieved through a variety of strategies, including recycling, reuse, and remanufacturing.

Recycling is one of the most effective ways to promote a circular economy in the steel industry. Steel is one of the most recycled materials in the world, with a recycling rate of around 90%. Recycling steel reduces the need for new raw materials, saves energy, and reduces greenhouse gas emissions. Recycled steel can be used to produce new products or to replace virgin steel in existing products, such as automobiles and appliances.

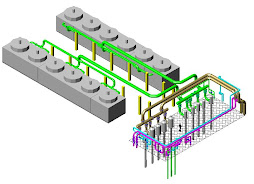

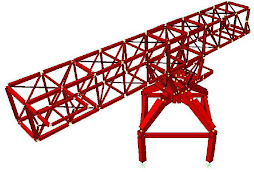

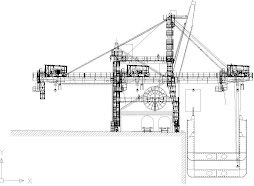

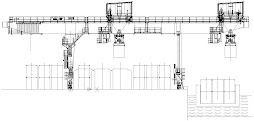

Another strategy for promoting a circular economy in the steel industry is reuse. Reusing steel products reduce the need for new materials and reduce waste. Steel products can be reused in a variety of ways, including as building materials, industrial equipment, and transportation infrastructure.

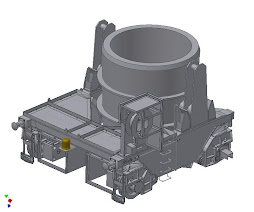

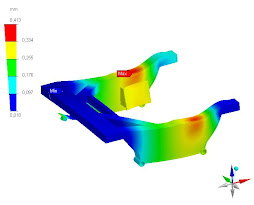

Remanufacturing is another strategy for promoting a circular economy in the steel industry. Remanufacturing involves taking used steel products and rebuilding them to like-new condition, extending their useful life and reducing the need for new materials. Remanufacturing can be used for a variety of steel products, including industrial equipment, automotive parts, and building materials.

Reducing the environmental footprint of the steel industry is another important goal. One way to do this is to reduce the energy and resource consumption of steel production. Energy-efficient technologies, such as electric arc furnaces and continuous casting, can help reduce energy use in steel production. Using renewable energy sources, such as solar and wind power, can also reduce greenhouse gas emissions from steel production.

Reducing waste and improving the recycling of steel products can also help reduce the environmental footprint of the steel industry. Steel products should be designed for easy disassembly and recycling, and end-of-life products should be collected and recycled whenever possible.

In conclusion, promoting a circular economy and reducing the environmental footprint of the steel industry is an important goal for engineers and stakeholders in the industry. Strategies such as recycling, reuse, remanufacturing, and energy efficiency can help achieve this goal, while also providing economic benefits and reducing the environmental impact of steel production. By working together to promote a circular economy and reduce the environmental footprint of the steel industry, we can create a more sustainable future for all.