Reverse engineering has become a vital component of modern product design and manufacturing processes, aiding industries such as aerospace, automotive, and industrial sectors. By replicating legacy parts, analyzing competitors' products, and enhancing existing designs, reverse engineering plays a crucial role in innovation. As technology advances, the hardware and software used for digitizing physical components into accurate computer-aided design (CAD) models also improve. In this article, we will explore the emerging trends that will shape the future of reverse engineering.

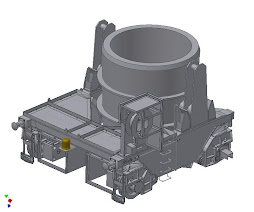

Rapid prototyping, the iterative process of developing physical prototypes or models quickly, has revolutionized product development. Manufacturers rely on this method to test and validate design ideas, minimizing costly mistakes and delays. Reverse engineering plays a pivotal role in rapid prototyping by creating digital models from existing products or parts. By utilizing 3D scanners, companies can capture and reverse engineer manufactured parts as a foundation for new designs. This approach not only expedites the development process but also enhances the final product's quality, saving significant time and effort.

-Additive Manufacturing:

The increasing adoption of additive manufacturing, also known as 3D printing, is another trend shaping reverse engineering. This advanced fabrication process constructs three-dimensional parts by layering materials based on a CAD file. Additive manufacturing has become more accessible and affordable, allowing a broader range of businesses to leverage its benefits. This development expands the scope of reverse engineering, enabling cost-effective replication of a wider variety of products. As additive manufacturing and scanning technologies progress, reverse engineering and printing software will continue to evolve, streamlining the reverse engineering workflow.

-Virtualization:

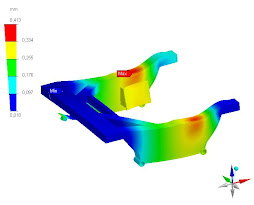

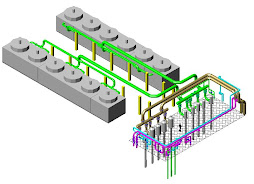

Virtualization, often used in conjunction

with reverse engineering, is an emerging approach integrated into manufacturing

workflows. It involves creating digital models or digital twins of physical

objects and optimizing their designs in a virtual space. Virtualization allows

users to interact with lifelike virtual prototypes, simulate product

performance under different conditions, and test ergonomics before physical

production. It also facilitates immersive learning experiences and enhances

collaboration among teams, regardless of their geographical locations.

Advancements in augmented reality (AR), virtual reality (VR), artificial

intelligence, and machine learning have made virtualization more accessible and

valuable for a wide range of industries. As virtualization becomes increasingly

prevalent, the demand for high-precision scanning technology and reverse engineering

software rises to create realistic and accurate 3D CAD models for virtual

setups.

The future of reverse engineering is poised to embrace the

transformative trends of rapid prototyping, additive manufacturing, and

virtualization. Manufacturers will leverage these technologies to accelerate

product development, improve design quality, and enhance collaboration. As 3D

scanning, printing, and virtualization tools become more affordable and

user-friendly, more individuals across various departments will have access to

them. This paradigm shift will enable companies to stay competitive, innovate

faster, and adapt to the evolving needs of the market. By embracing these

trends, businesses can unlock new possibilities and revolutionize their reverse

engineering processes in the years to come.

At Ideco, we offer advanced 3D scanning technology and comprehensive testing tools to digitize objects and extract valuable data. If you're looking for reliable reverse engineering services, contact us now to receive a personalized quote.