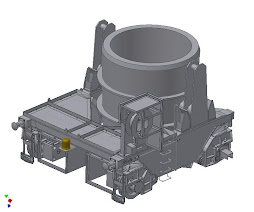

In the dynamic world of mining, equipment design plays a pivotal role in ensuring safety, efficiency, and productivity. As demands grow, so do the complexities. In this article, we delve into the vital role of 2D/3D design tools and cutting-edge software like BricsCAD, BricsCAD Communicator, TechnoMetal, AVICAD, Solid Edge 3D Shining, CFAST7, and FDS in crafting superior mining equipment designs.

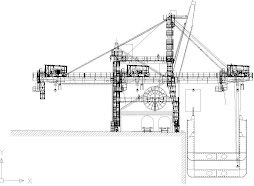

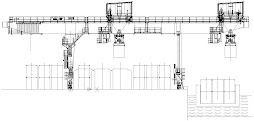

The Power of 2D/3D Design:

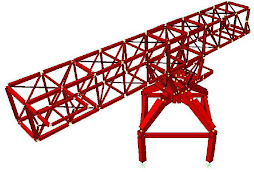

2D and 3D design tools provide

the foundation for conceptualizing, visualizing, and refining mining equipment.

The synergy between these tools enables designers to create intricate models,

simulate real-world scenarios, and make informed decisions that optimize

equipment functionality and minimize risks.

BricsCAD:

BricsCAD emerges as a game-changer,

offering both 2D and 3D capabilities under one roof. This versatile platform

empowers engineers to seamlessly transition between design phases, ensuring a

comprehensive and coherent design process.

BricsCAD Communicator:

The integration of BricsCAD

Communicator enhances collaboration by importing geometry and PMI data from

diverse CAD applications. This ensures seamless communication and alignment

among multidisciplinary teams, from design to manufacturing.

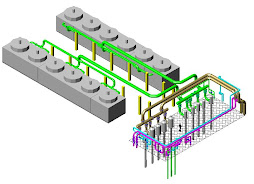

TechnoMetal & AVICAD:

These tools provide specialized

functionalities that cater to the unique demands of mining equipment design.

With modules tailored for mining applications, they streamline the design

process, reducing iterations and accelerating project timelines.

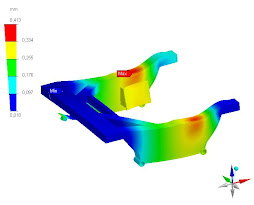

Solid Edge 3D Shining:

With its robust 3D design

capabilities, Solid Edge empowers engineers to explore complex geometries,

intricate assemblies, and simulate real-world conditions. This aids in

identifying design flaws early on, minimizing costly modifications during

manufacturing.

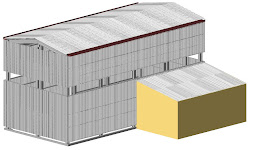

CFAST7 & FDS:

In the realm of safety, CFAST7

and FDS (Fire Dynamics Simulator) emerge as indispensable tools. They allow

engineers to simulate fire scenarios, ensuring that equipment designs are not

only efficient but also compliant with stringent safety regulations.

Conclusion:

Mining equipment design is a

challenging landscape, but armed with the right tools, it becomes a realm of

boundless possibilities. The synergy between 2D/3D design, innovative software,

and specialized modules offers a holistic approach to crafting equipment that

thrives amidst adversity. As the mining industry evolves, so do our practices,

pushing the boundaries of what's achievable and safe.

At IDECO Heavy Equipment, we

leverage these tools and practices to redefine excellence in mining equipment

design, ushering in a new era of safety and efficiency.