As mechanical engineers working in bulk material handling, we frequently encounter complex challenges that require both analytical rigor and innovative problem-solving approaches. Today, we'll examine two real-world case studies that demonstrate how systematic engineering analysis can transform operational failures into reliable, optimized systems.

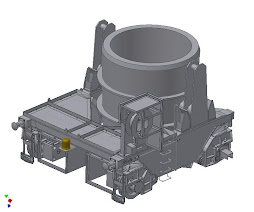

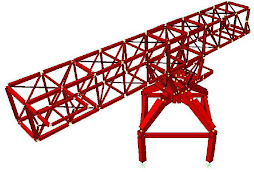

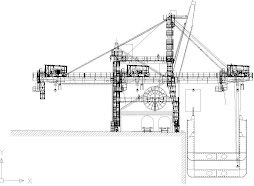

Case Study 1: Bucket Wheel Stacker/Reclaimer Structural Failure

The Problem

A bucket wheel stacker/reclaimer experienced a critical structural failure at the connection between the gantry and traveling system. This type of failure poses significant safety risks and can result in extended downtime, making it a priority for immediate analysis and remediation.

Root Cause Analysis

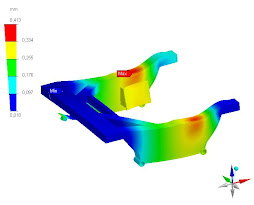

Using Finite Element Method (FEM) analysis, the investigation revealed that the failure occurred due to the absence of an internal diaphragm at the section reduction point. This missing structural element created a stress concentration that exceeded the material's capacity under operational loads.

The FEM analysis clearly highlighted how the section transition without proper internal reinforcement led to inadequate load distribution and subsequent structural compromise. This finding underscores the critical importance of proper structural continuity in heavy machinery design.

Engineering Solution

Given the operational constraints of the existing equipment, installing a traditional internal diaphragm was not feasible. The engineering team developed an innovative approach: implementing external reinforcement that provides equivalent structural resistance to the missing internal diaphragm.

This solution demonstrates the flexibility required in retrofit engineering projects, where ideal theoretical solutions must be adapted to real-world constraints while maintaining structural integrity.

Implementation

The final phase involved producing detailed workshop drawings for the external reinforcement system. This documentation ensured that the fabrication and installation would meet the calculated structural requirements while being practical for field implementation.

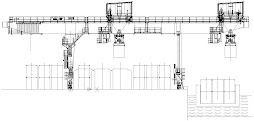

Case Study 2: Coal Hopper Flow Optimization

The Challenge

A coal handling facility was experiencing recurring operational shutdowns due to material clogging in the hopper system. The material would overflow, requiring manual intervention and plant shutdowns – a costly and inefficient operational scenario.

.jpeg)

Technical Analysis

The investigation revealed multiple contributing factors:

- Material adhesion: Coal was gradually sticking to the hopper walls, progressively reducing the effective flow area

- Incorrect wall angles: The chute walls were designed without proper consideration of the material's angle of repose and complementary angles

- Undersized sections: The chute geometry was inadequate for the material flow requirements

Advanced Simulation Approach

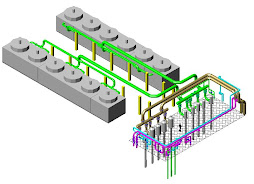

The engineering team employed Discrete Element Method (DEM) simulation to model the material properties and analyze flow behavior. This computational approach allowed for:

- Accurate prediction of particle behavior under various geometric configurations

- Optimization of wall angles based on actual material properties

- Validation of proposed solutions before physical implementation

Validation and Standards Compliance

Critical to the project's success was the validation of DEM calculations against established engineering standards. This step ensures that simulation results translate reliably to real-world performance and meet industry requirements.

Optimized Design Solution

Based on the simulation results, a new discharge system was developed that addressed all identified issues:

- Proper wall angles accounting for material characteristics

- Optimized section sizing for adequate flow capacity

- Surface treatments to minimize material adhesion

Key Engineering Takeaways

1. Systematic Analysis is Essential

Both cases demonstrate the importance of thorough root cause analysis. Rather than implementing quick fixes, systematic investigation using appropriate analytical tools (FEM for structural issues, DEM for material flow) leads to more effective and lasting solutions.

2. Simulation Tools Enable Better Design

Modern computational tools like FEM and DEM simulation allow engineers to understand complex behaviors that would be difficult or impossible to analyze using traditional methods. These tools enable optimization before physical implementation, reducing risk and cost.

3. Practical Constraints Shape Engineering Solutions

The bucket wheel case illustrates how engineering solutions must balance theoretical ideals with practical constraints. Sometimes the best engineering solution isn't the most obvious one, but rather the one that can be effectively implemented within existing limitations.

4. Material Properties Drive Design

The hopper case emphasizes how critical it is to understand and incorporate actual material properties into design decisions. Generic approaches often fail when material-specific characteristics like angle of repose, particle size distribution, and adhesive properties aren't properly considered.

5. Validation Ensures Reliability

Both projects included validation steps – whether through standards compliance or field verification. This validation phase is crucial for ensuring that analytical results translate to reliable operational performance.

.jpeg)

Conclusion

These case studies illustrate the multidisciplinary nature of modern mechanical engineering in bulk material handling. Success requires not only strong analytical capabilities but also practical problem-solving skills, advanced simulation tools, and a thorough understanding of material behaviors.

For mechanical engineers working in similar applications, these examples highlight the value of:

- Comprehensive failure analysis using appropriate computational tools

- Creative problem-solving when standard solutions aren't feasible

- Material-specific design approaches rather than generic solutions

- Rigorous validation against established standards

The integration of advanced analysis tools with practical engineering judgment continues to be the foundation of successful bulk material handling system design and optimization.

The case studies presented here demonstrate real-world applications of engineering analysis in bulk material handling systems. For complex projects requiring similar expertise, consulting with specialized engineering firms can provide the analytical depth and practical experience necessary for successful outcomes.

Nessun commento:

Posta un commento